A

Re-Useable

Spiderweb Coil

Form

by

Mike

Tuggle's

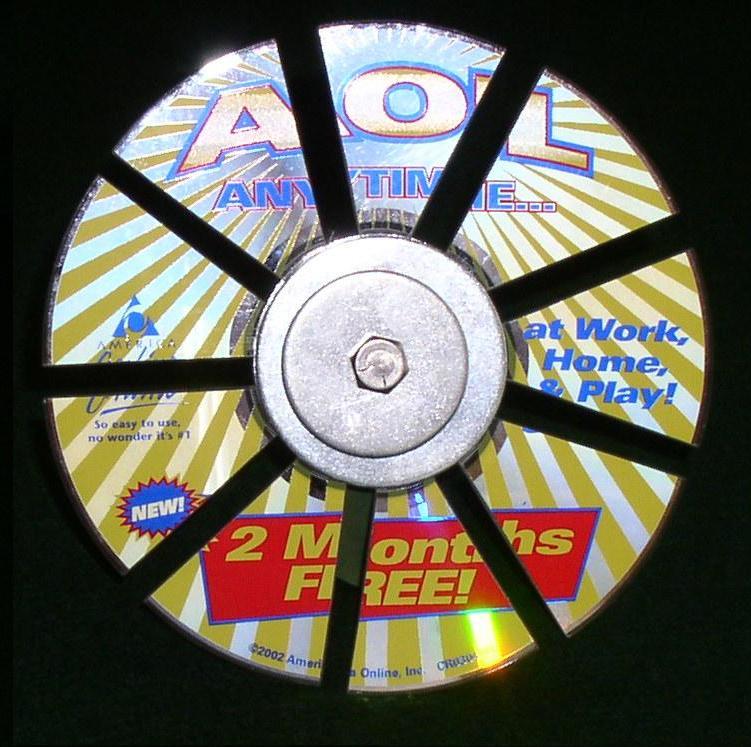

A lot of recent discussion has centered about using

those

useless AOL

Free Offer CDs as spiderweb coil forms. The suggested ways to do

this all seem to involve a lot of power equipment, including table saws

and milling machinery -- nice, if you have it. Also involved is a

lot of sanding to remove the metal foil which otherwise would ruin the

disk as a coil form. I figured there's got to be a simpler

way.

Here's one that's a little simpler, and it doesn't involve powered

equipment

or extensive sanding.

I'm not sure how the old wives' tale about 'brittle

CD

disks' came

about -- or why it continues to be perpetuated. In fact CDs,

being

acrylic plastic-metal foil laminate, are tough as nails. Try to

snap

one in half -- sure, you can get it into two pieces after repeatedly

bending

it until it fails. Point is, they are sturdy.

For a nine-section form draw a 40-degree angle on

some

paper.

Center the CD on the apex (shiny side up works best) and trace the

cut-lines

with a sharp scribing tool or knife blade. Continue to mark off

40-degree

lines, first to one side, then to the other, working your way around

the

disk. How close that last pie section is to 40 degrees depends on

how carefully you marked off the other cut lines. If it's off a

little

bit, no big deal -- this won't show in the final coil.

Now, hacksaw the CD into nine 40-degree pie

sections.

Some

points: Use a fine '24 tooth' or finer blade. Hold the disk

so the cut line rests at the edge of a block of scrap wood -- this

makes

a useful guide for a straight cut. Patience is the keyword here

--

the plastic heats up at the cut point and will tend to 'grab' the blade

-- back off for a few seconds, then continue cutting. The last

cut

is toughest -- very little disk left to hold onto.

Sand all the cut edges to remove plastic and foil

burrs.

The hub that holds these pie sections (vanes) is a

sandwich

of two

2-in. dia. fender washers and a 1/4-in. bolt. As you can

see,

I've also stacked 1-1/2-in. washers on either side to 'even out' the

bolt's

pressure. I guess this works.

The tips of the pie sections are inserted into the

sandwich, up to

the raised CD hub ring. Because the hub ring, originally

11/16-in.

radius, is now spaced out to a 1-in. radius, wider (approx. 1/4-in.)

gaps

fall between the pie sections, making for easy winding.

Using

the logo side as a guide, I assemble the pie sections in their original

order in case there were irregularities in my saw cuts. This

assembly

is the trickiest part -- get all the pie sections inserted without

worrying

about their spacing around the hub. Then tighten the bolt so that

all pie sections are held in but can be wiggled about. If one pie

section still wants to fall out, place a single layer of tape (masking,

cello-) on the inside faces of the big washers.

Once all pie sections are more-or-less equally spaced

about

the hub,

give the bolt a final tightening. There's your form. Happy

winding !

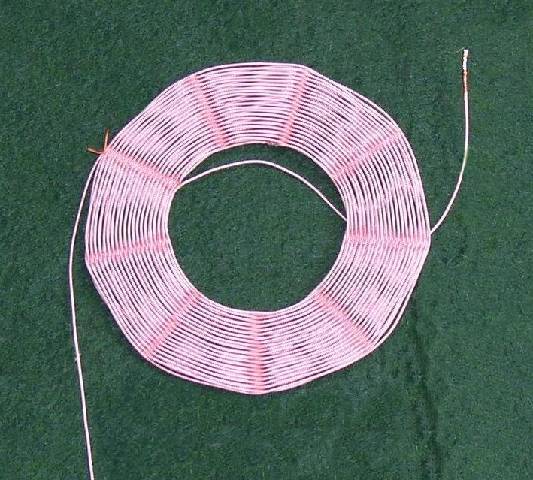

Once your coil is wound ...

apply, sparingly, a bead of glue along the wire

crossover

lines in

the slots. Flip the coil over, and do the same for that

side.

I say sparingly, because the idea is to not glue the wire to a pie

section.

If you don't believe enough glue has been applied to hold the coil

together,

let it dry and repeat gluing.

Styrene-based 'coil dope' is a good glue for this --

it's

supposedly

low loss. You can make your own by dissloving styrofoam into

lacquer

thinner (not acetone). A milliliter or two of lacquer thinner

will

be more than ample for several coils -- and you will be truly amazed at

how much styrofoam must be dissolved in this to give even a thin

glue-like

consistency. In standard units, two milliliters will dissolve at

least 20 styrofoam peanuts. I see some peanuts are foamed

polyethylene

-- I got my doubts whether they will dissolve. If you're not sure

test them out with a drop of lacquer thinner.

After all is glued and dried, the hub is unbolted and

pie

sections

removed. Formless and self-supporting -- works like a

charm.

I used a loop of thread to further secure the very start and end of the

winding.

Mike Tuggle

Finished Coil With Form Removed!!

|